3D-printing of Generative Art by using Combination and Deformation of Direction-specified 3D Parts

Kanada, Y., 4th International Conference on Additive Manufacturing and Bio-Manufacturing

(ICAM-BM 2014, Beijing), 2014-11.

[ 日本語のページ ]

[ Slides PDF file (w/o video) to be uploaded ]

[ Slides (Keynote file with video, for Macintosh) ]

[ Paper PDF file - not presented at the conference ]

[ "Generative art" shop (Japan only) ]

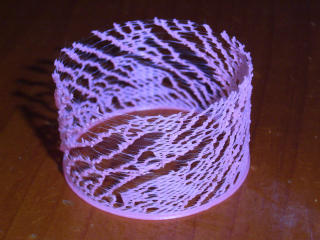

Abstract: Direction-specified 3D modeling and FDM-based printing methods enable expression of natural directions, such as hairs, fabric, or other directed textures, in modeled objects. This paper describes a method for creating various shapes of generative artistic objects with several specialized attributes by applying three new techniques to the direction-specified methods for better artistic expressions. The most important technique is “deformation”, which enables deforming simple 3D models to create varieties of shapes much more easily in generative design processes. The second technique is called the spiral/helical printing method, which enables consistent print-direction vector field, i.e., filament directions, of the surface consistent with those of the interior portion and enables seamless or less-seam printing results. The third technique controls light reflection while printing by using the spiral/helical printing method with transparent PLA. It enables the printed objects reflect light brilliantly. The proposed method with these three techniques was implemented as a Python library and evaluated by printing various shapes, and it is confirmed that this method works well and objects with attractive attributes can be created.

Introduction to this research theme: 3D shape formation technologies

Abstract: 3D printing technology usually aims at reproducing objects deterministically designed by 3D CAD tools; however, the author has discovered that 3D printing can also generate self-organizing patterns similar to stochastic (or randomized) 1D cellular automata (CA). A method for generating patterns similar to randomized 1D or 2D CA by using a fused deposition modeling 3D printer is thus proposed. With constant head motion and constant filament extrusion and without explicit randomness, this method generates very fine emergent patterns with natural fluctuation. By means of this method, each time a different pattern is generated. In addition, a computational CA model that simulates the above process is also proposed. The proposed method will open a new horizon of 3D printing applications.

Abstract: 3D printing technology usually aims at reproducing objects deterministically designed by 3D CAD tools; however, the author has discovered that 3D printing can also generate self-organizing patterns similar to stochastic (or randomized) 1D cellular automata (CA). A method for generating patterns similar to randomized 1D or 2D CA by using a fused deposition modeling 3D printer is thus proposed. With constant head motion and constant filament extrusion and without explicit randomness, this method generates very fine emergent patterns with natural fluctuation. By means of this method, each time a different pattern is generated. In addition, a computational CA model that simulates the above process is also proposed. The proposed method will open a new horizon of 3D printing applications.