Self-organized 3D-printing Patterns Simulated by Cellular Automata

Kanada, Y., 20th International Workshop on Cellular Automata and Discrete Complex Systems (Automata 2014), July 2014.

[ 日本語のページ ]

[ Paper PDF file ]

[ Paper PDF file (extended ver. for IWNC8 book) ]

[ Slides (reduced size) ]

[ Slides (with a movie, Keynote) ]

[ Printing process (YouTube) ]

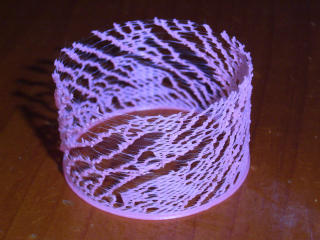

Abstract: 3D printers are usually used for printing objects designed

by 3D CAD exactly, i.e., deterministically. However, 3D printing process

contains stochastic self-organization process that generate emergent

patterns. A method for generating fully self-organized patterns using a

fused deposition modeling (FDM) 3D printer has been developed. Melted

plastic filament is extruded constantly in this method; however, by using

this method, various patterns, such as stripes, splitting and/or merging

patterns, and meshes can be generated. A cellular-automata-based

computational model that can simulate such patterns have also been

developed.

Abstract: 3D printers are usually used for printing objects designed

by 3D CAD exactly, i.e., deterministically. However, 3D printing process

contains stochastic self-organization process that generate emergent

patterns. A method for generating fully self-organized patterns using a

fused deposition modeling (FDM) 3D printer has been developed. Melted

plastic filament is extruded constantly in this method; however, by using

this method, various patterns, such as stripes, splitting and/or merging

patterns, and meshes can be generated. A cellular-automata-based

computational model that can simulate such patterns have also been

developed.

Introduction to this research theme: 3D shape formation technologies